Sherrell Greene's research at ORNL included exploration of Fluoride Salt Cooled High Temperature Reactors (FHRs). Molten Salts can be used as both reactor coolants and as reactor coolants/fuel carriers. Advanced High Temperature Reactors (AHTR) are hybrid reactors which combine features of Molten Salt Reactors with features of Gas Cooled Graphite Structured or of Pebble Bed Reactors. The nuclear fuel for AHTRs is solid and embedded in graphite structures rather than a liquid salt dissolved in liquid salt coolant/carriers. SmAHTRs are Small Advanced High Temperature Reactors. (Sherrell Greene's web site can be found at, www.SherrellGreene.com.)

(Questions 12 and 13 have been omitted.)

14. What do you view as the advantages of Molten Salt cooled Advanced High Temperature Reactors (AHTR)?

First, to avoid confusion, at ORNL we developed some terminology I would like to see adopted more widely. We liked to call liquid salt-cooled reactors, “FHRs” – Fluoride salt cooled High temperature Reactors. These are salt-cooled, but not salt fueled. Then, of course, there’s the molten salt reactors or “MSRs”, with are both cooled and fueled with fluoride (or possibly chloride) salts.

The first FHR concept ORNL developed in conjunction with SNL and others, was the Advanced High Temperature Reactor (AHTR) in the early 2000’s. The AHTR in a large GW+ class central-station electricity generator. The second concept we developed during the past year or so was the Small modular Advanced High Temperature Reactor (SmAHTR). SmAHTR is a 125 MWt / 50+ MWe modular FHR for both process heat and electricity production.

In my view, FHRs integrate the best attributes of liquid metal-cooled reactors (LMRs), gas-cooled reactors (GCRs), and molten salt-cooled reactors (MSRs). They are high-to- very-high temperature, low pressure systems. They employ fluoride salt coolants, TRISO particle graphite fuels, and Brayton power conversion systems. Due to their low pressure, salt coolants, and graphite fuels, they inherit the best safety attributes of LMRs, GCRs, and MSRs. They inherit the economic advantages of low pressure systems – which means thinner-walled vessels and piping.

However, FHRs have their own issues. The favored fluoride salt (FLiBe) is very expensive. The high-temperature salt-tolerant structural materials are expensive. There are tritium control issues. And since you have to make the jump from a low pressure reactor to a high-pressure power conversion system in the electricity production application, there are a number of component design and reliability challenges – particularly with regard to heat exchangers.

Having said all of that, I’m big on the promise of FHRs.

15. How might the development of the AHTR contribute to the development of the MSR?

In many ways. In order to successfully develop and deploy an FHR, one must solve many of the fundamental technology challenges required for MSRs: the fluoride salt supply chain, the structural materials supply chain, fluoride salt pumps and heat exchangers, tritium control, instrumentation and control technologies... just to name the more important technologies. The development of an FHR would leave the country with a robust development infrastructure for MSRs. And the successful deployment of an FHR would be a path-finder for the licensing and regulatory framework environment required for successful MSR deployment. However, the fact that MSRs have a liquid, mobile fuel will be a large, unaddressed hurdle in the regulatory arena.

16. What do you view as the potential uses of the AHTR?

High-to-very high temperature process heat and high-efficiency electricity production for central station and remote applications.

17. Does the AHTR have a potential cost advantage compared to the LWR?

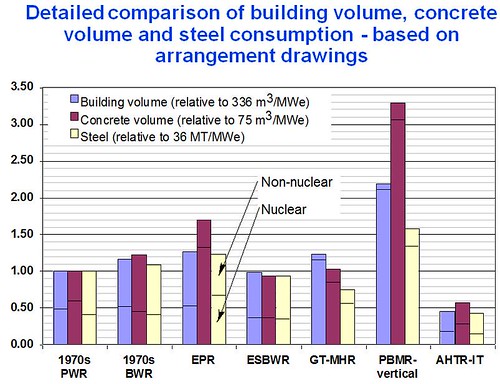

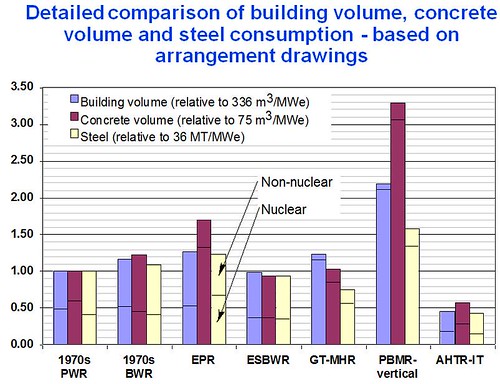

Yes. Their low pressure character translates to less metal in their construction. The coolant doesn’t interact energetically with air/water. This means one is not driven to massive containments. Less concrete. SmATHR could benefit enormously from factory fabrication. However, there are off-setting issues. I’ve already mentioned that fluoride salt coolant is really expensive. The nickel alloy structural materials aren’t cheap either.

ORNL and UC-Berkeley have both published analyses that indicate the FHRs should be competitive or superior in cost performance to modern LWR technologies. However, I would caution that due to the relative immaturity of the AHTR and SmAHTR concepts, it isn’t feasible to do the detailed bottoms-up cost estimates that support a truly compelling case at this point. We need to bring the concepts along to a higher degree of fidelity before that is really possible.

18. What are the AHTR potential safety advantages?

TRISO graphite fuel is a very robust high-temperature fuel form and operates with large thermal margins in FHRs.

Fluoride salt doesn’t react energetically with air or water.

Fluoride salt is an extremely attractive heat transport medium. This means less coolant to be pumped during operation, and the core can be cooled effectively with passive decay heat removal loops after shutdown.

Low pressure systems remove a major mechanical driving force for expulsion of radioactivity from the reactor system in the event of an accident.

19. Does the AHTR have potential safety advantages in comparison with advanced LWRs?

I believe FHRs do have advantages due to the attributes I mentioned above.

20. What are the useful characteristics of the Small Modular Advanced High Temperature Reactor (SmAHTR)?

SmAHTR can be factory fabricated, transported by a large semi-tractor trailer rig, and “installed” on site. It is a dual function high-temperature process heat and electricity producer. When coupled with the “salt vault” energy storage system, they can be clustered to meet a variety of power and energy demands.

21. What contributions would you foresee the SmAHTR making to Post-carbon energy technology?

An entry-level or prototype SmATHR would probably operate at ~600oC to 700 oC. Later systems would probably move up to 800 oC to 850 oC as materials performance limits are resolved. In theory, there’s no reason a SmAHTR or an AHTR couldn’t operate as high as 1000 oC – but that’s a long-term goal. In its early manifestations, SmAHTR and AHTR could provide high quality process heat required for production of a variety of fossil-based synthetic liquid fuels, hydrogen, and ammonia. Charles Forsberg, formerly at ORNL and now at MIT, is exploring such “hybrid energy system” concepts.

(There is no question 22.)

23. What would the SmAHTR do better than any other post-carbon energy technology currently being considered?

Well, it has the potential to be a game-changing high-temperature process heat system – particularly when coupled with the “salt vault” energy storage system I described in the SmATHR pre-conceptual design report (ORNL/TM-2010/199). I’m tempted to say, “Anything a gas-cooled reactor (GCR) can do, an FHR can do better”. But the fact is we know more about GCRs than we do FHRs at this point. So it’s a bit premature to make that claim.

24. What would be the safety advantages of the SmAHTR?

It has most of the advantages of an MSR and it’s small. The differences are almost entirely a function of utilizing solid TRISO fuel in the FHR rather than the liquid fuel of the MSR: Discrete fuel that can’t leak, high thermal margins, low pressure, relatively inert coolant in terms of interaction with air and water, the ability to remove decay heat passively, etc. It’s also an integral primary system concept, with no reactor vessel penetrations so traditional pipe-break loss of coolant accidents are precluded by design.

25. Would there be any serious safety problems for the SmAHTR?

None that I am aware of. However, I would want to really understand air-ingress accidents in FHRs due to their use of graphite fuel and other graphite structures in the reactor vessel. Refueling operations are also due serious scrutiny.

26. Do you believe that SmAHTRs can serve as the basis of a new energy related enterprise?

On paper, SmAHTR is excellent choice for distributed hybrid energy systems such as those Charles Forsberg likes to discuss. In our SmAHTR pre-conceptual design report (ORNL/TM-2010/199), I described an integrated “salt vault” energy storage system that could be a key enabler of multi-functional FHRs.

27. How much would it cost to develop an SMAHTR prototype?

A lot. That’s the case for any new reactor. If by prototype, you mean an NRC-certified design and functioning prototype, simply look at the investment today’s commercial rector vendors are making to secure a design certification for a new evolutionary LWR. It’s in the neighborhood of $0.5–1B dollars. But we are not in a position to estimate SmAHTR’s development cost until the concept is more mature. Reactor development is a “deep pockets” endeavor.

28. What could an SmAHTR do better than a Molten Salt Reactor (MSR)?

I haven’t looked specifically at the question. So my answers are fairly speculative. Given my view that FHRs would probably be easier to commercialize than MSRs, I would turn your question around and ask, “What can an MSR do better than an FHR?” My instincts are that in terms of the basic functions of high-temperature process heat production and high-efficiency electricity production, FHRs such as SmAHTR and the MSRs are equals. Due to the differences in fuel, they will have different waste streams. I don’t think we understand that issue well. SmAHTR is a uranium-based, thermal spectrum system. Right now, the reference SmAHTR concept employs a cartridge core comprised of hexagonal fuel assemblies employing graphite fuel plates. There’s more trade study work to be done to optimize the core configuration. Both pebble-bed cores and cores comprised of discrete fuel assemblies are possibilities. Per Peterson’s team at UC-B have looked at pebble bed FHRs and seed-blanket thermal breeding strategies. We’ve not looked at a SmATHR breeder. But I think the MSR has the potential to be a better thermal breeder than the FHR. The MSR probably would also have an advantage in terms of assured shutdown mechanisms due to the ability to use freeze plugs in the fuel loop. The flip side is that MSRs have the potential for fuel leaks and FHRs don’t. Finally, since there is, at least on paper, the potential for a fast-spectrum MSR, the MSRs almost certainly have an advantage for actinide burning.

One thing I would add... SmAHTR is an integral primary system design. Previously MSRs concepts have been loop designs. In my view, they’ve been plumber’s nightmares. That’s one of the reasons ORNL abandoned the two-fluid Molten Salt Breeder Reactor (MSBR) concept. If you look in detail at the Molten Salt Reactor Experiment (MSRE) at ORNL, they had many, many side streams of hot liquid salt. That was appropriate for an experiment and necessary at the time for a variety of reasons. But, today one would never design a commercial reactor that way. My friend Jess Gehin at ORNL and I have been discussing the idea of an integral-design MSR for some time. We believe integral concepts could potentially improve the reliability and operability of the MSR concept.

29. Might the SmAHTR be viewed as a stepping-stone to MSR development?

Absolutely. I believe a small FHR would be easier to design and license from the overall plant perspective. One doesn’t face all the salt processing and and flowing-fuel challenges posed by MSRs. However, one must again proceed with a hefty dose of humility here. FHRs are paper reactors. And there is no modern MSR design. So we do not have FHR or MSR design criteria. We do not have the FHR and MSR design details required for development of a PIRT (phenomena identification and ranking table) – much less the detail needed to conduct PRAs. There’s no licensing roadmap for either concept. That said, the MSR employs a flowing fuel that must be kept contained under all circumstances. This creates a plethora of design challenges that have never been faced in a modern regulatory environment. From the plant design perspective the flowing mobile fuel impacts system complexity and redundancy, plant reliability, plant cost, and licensing difficulty. The FHR does not have to face those challenges.

Finally (though many in the FHR and MSR community would not agree with me) I am concerned about the overall cost (supply chain, operations, and disposal) of FLiBe. I believe it could be an impediment to deployment of FHRs and MSRs. In my view, FLiBe is the worst possible FHR/MSR salt – other than all the other salts (laugh). It’s wonderful in terms of its integrated nuclear, thermal, and thermalhydraulic performance. However, the cost of removing the Lithium-6 will be high. An you still have to worry about tritium production after you do it. Beryllium is also a human occupational risk and environmental disposal issue. So I wish we could develop an affordable alternate coolant salt that performs as well as FLiBe. There’s been little serious coolant salt design work since ORNL’s original efforts in the 1950’s and 1960’s. I think we have a shot at developing a good alternative if we really applied ourselves. In the mean time, FLiBe’s overall performance is compelling.

Showing posts with label MSRs. Show all posts

Showing posts with label MSRs. Show all posts

Tuesday, November 15, 2011

Monday, September 26, 2011

Underground Reactor Advantages

Underground sited. This scale was chosen so that the physical size allowed it to be factory manufactured and transported to the site,which is a significant potential cost reducer. . . .- John Rawls, Chief Scientist at General Atomics

From the dawn of the Nuclear era, Edward Teller was deeply concerned about reactor safety. Teller favored underground placement of civilian nuclear power plants primarily for safety reasons. Indeed in his last paper Teller advocated underground placement of Molten Salt Reactors, although arguably MSRs could be designed to be safe enough to make further safety measures unnecessary. A further justification of underground placement of MSRs, would be that it would be consistent with low manufacturing costs and rapid reactor deployment.

Underground deployment of nuclear tractors offers a number of advantages including,

Underground placement of small, compact Generation IV nuclear power plants would be inexpensive, and underground placement is often featured in many small Modular nuclear designs including the B&W mPower Reactor. A recent report to the American Nuclear Society by Mark S. Campagn and Walter Sawruk and titled, "PHYSICAL SECURITY FOR SMALL MODULAR REACTORS" states,

Higher Resistance to...

– Terrorist attack

– Aircraft impacts

– Proliferation

– Sabotage and vandalism

– Conventional warfare effectsUnderground sites offer superior protection against the effects of severe weather events and some potentially protection even from the effects of earthquakes. Underground sites also offer superior protection against fission product release in the event of a serious reactor accidents. Studies of underground siting conducted during the 1970's reported that underground siting would cost more than traditional reactor siting, but these studies assumed the use of conventional nuclear technology and that the entire nuclear facility would be located underground. From the viewpoint of safety and security it is only necessary to house reactors underground. Turbines and generators, as well as other Nuclear Power Plant related facilities can be located above ground without any disadvantages if the cost of underground facilities placement become a matter of concern. In addition Generation IV reactors are generally more compact than conventional reactors. There are other ways to limit underground housing costs. For example salt formations offer unique advantages for nuclear reactor housing, with low cost excavation. Existing underground salt mines offer unique placement advantages. In addition to existing salt mines, many old mines and natural caverns offer potential underground siting for reactors. Studies of underground placement of nuclear facilities made during the 1970's assumed that reactors would be placed 300 feet or more beneath the surface, but reactor manufacturer Babcock and Willcox intend to place their small mPower Reactor just below the surface.

Underground placement of small, compact Generation IV nuclear power plants would be inexpensive, and underground placement is often featured in many small Modular nuclear designs including the B&W mPower Reactor. A recent report to the American Nuclear Society by Mark S. Campagn and Walter Sawruk and titled, "PHYSICAL SECURITY FOR SMALL MODULAR REACTORS" states,

Rely on government response for SMR facilities with vital assets underground or otherwise well protected. Shallow burial or a hardened structural design provides excellent protection against large explosive weapons and aircraft impact as well as an excellent means of enhancing security system effectiveness against sabotage. Application of the traditional multilayered defensive approach of detection, deterrence, delay, and defeat can be used effectively for physical protection of SMRs. Detection, deterrence, and delay concepts must be integrated into the early design phase of the facility in order to provide sufficient lead time for government response.A few years ago three University of Tennessee Nuclear Engineering Graduate students, William A Casino, Kirk Sorensen, and Christopher A Whitener wrote a paper titled "A Small Mobile Molten Salt Reactor (SM-MSR) For Underdeveloped Countries and Remote Locations." The paper won first prize in an American Nuclear Society reactor design contest. This design exercise focused on a reactor small enough to be transportable by truck, yet large enough to be transportable by truck. The design is highly suggestive although it turns out to be a little big to be truck transported. The reactor was designed to produce 100 MWe, with an active core region that weighed 216 tons (about 200 metric tons). This is too heavy to be easily transported by truck, but it might be possible to shave that weight down significantly. More than half of the core weight is contributed by core graphite (about 147 of 215 tons). Thus a method of inserting core graphite into the core at the destination site, would offer considerable advantage if this could be accomplished quickly and at low cost. The use of graphite pebbles would be consistent with these goals. This would lower of the weight of the core moduel to 68 US tons, which would certainly be manageable by either truck or train. Further the primary heat exchange and connecting pipes are included in the core module, and this might be considered a flaw in the design.

There were a number of flaws in the SM-MSR design, which was after all a student design exercise. Although a core dump tank was included in the SM-MSR design, no colling system was included. However, a passive cooling system for the disposal of fission product decay heat is possible with an underground MSR. Air can be drawn into the underground chamber and heated by the dump tank exterior, and then the heated air could rise through a chimney. The rising heated air, would, of course, draw more air into the underground chamber by lowering its air pressure, thus creating a passive decay heat cooling system.

Casino, Sorensen, and Whitener noted that,

One site specific limitation is that the primary containment module as proposed is to be placed into a silo to be trenched into the earth. This silo needs to be approximately 28 meters in depth and be approximately 25 square meters in area. The water table in most locations will likely occur above this level, and the SMMSR containment module shall be constructed to withstand moisture impingement on the outer surface. Other corrosive elements in the water need to be checked for.The reactor silo would not requite a significant amount of excavating, and thus could be dug quickly. As has already pointed our, building a silo from scratch might not always be required. Silos built for cold war guided missles, and well as a variety of underground mines might be useful, although preexisting underground structures would not be the only solution to small reactor siting the problem. Rapid drilling of a silo could advance at rates of as much as 10 meters a day. With prefacricated silo liners, site preperation might require no more than a week. Thus the re-use of coal fired power plants sits to house clusters of small baseload reactors could easily include underground housing of a number of reactors.

Underground housing of small reactors appears to be practical and it is credible to argue that Underground reactor housing can lower nuclear costs, and dramatically shorten reactor construction times. In addition underground housing can increase nuclear safety and offer significant protection of reactors from aircraft and other forms of terrorist attacks.

Tuesday, August 30, 2011

MSR/LFTR development and Chinese Economic Growth.

Note: This is the third part of an three part essay on the the the future non proliferation policies of India and China with respect to the thorium related technologies. The second part of this essay discussed the role of Thorium in India's nuclear development program, and Indian past, present and possible future attitudes towards nonproliferation.

Despite the current extremely robust growth of the Chinese economy during the last decade, some economists, looking ahead see clouds on the horizon. Michael Pettis is a professor at Peking University's Guanghua School of Management, and author of the well received book, The Volatility Machine: Emerging Economics and the Threat of Financial Collapse. Pettis is a pessimist about the stability of the international finance order, and sees international boom and bust monitary cycles effecting the economies of developing countries even more than the econmies of developed countries. In a recent article in China Financial Markets, Professor Pettis argues that

It is my view that even if this socio-economic and political crisis strikes China, Global awareness of the grave implications of continued reliance of carbon based energy sources will rise rise rapidly. Thus at the same time China may faces an economic crisis. Even if more conventional estimates of the developmental course of turn out to be correct, China will be faced with the problem of shifting its energy system to post-carbon energy technologies.

Thus what ever the course of the Chinese economy, the need to replace energy from fossil fuel sources, with energy from post carbon sources will start to become acute within the next ten years. Thus what ever its economic situation, China will require rapidly scalable energy technologies that can replace coal and other fossil fuels. At the moment, China appears committed to developing LFTR technology. On February 2, in the wake of the Chinese LFTR announcement I stated on Nuclear Green, I stated:

No accurate estimate of China's Thorium reserve is available, but thorium is a common mineral in rare earth mining tilings, and China's rare earth mining industry is by far the largest in the world. My guess is that China holds enough thorium above ground now, to power the entire Chinese economy for hundreds if not thousands of years. The energy potential of this internal, low cost energy source is attractive to China, which like India is dependent on foreign uranium sources for a uranium powered economy, would prefer to have total control of its energy resources.

Historically China has been economically self contained, and although Chinese economic development has focused on international trade, Professor Pettis offers the view that future Chinese economic development will focuse on the growth of internal markets. In addition the Chinese government is under great though largely hidden pressures to clean up environmental problems. Shifting from coal to Thorium would solve serveral environmental problems at the same time. A shife from trade to internal economic grown and increasingf environmental concerns thus point to a rational for thorium energy use as a matter of national policy.

The historic foreign policy of China has usually been to exercise hegemony over its neighbors but to not incorporate them into its empire. In addition, the Chines state has usually defended its territory rather than sought expansion. The present Communist government has acted to insure that traditional Chinese imperial territory remain part of China. The 1949 invasion of Tibet, and the continued Chinese insistence that Taiwan is part of China are evidence of that poi icy, The Chinese Government is also concerned about border defenses, and the 1962 war between China and India was motivated by Chinese desires to obtain defensible southern borders.

Finally China has cooperated with American Nonproliferation policies only when it is in Chinese interests to do so. China has in the past been willing to transfer of nuclear weapons technology and even weapons grade nuclear materials, when the development of nuclear weapons by other states furthered what Chinese leaders viewed as China's national interest. China has viewed India as a potential enemy, and thus its allied itself with another enemy of India Pakistan. China reportedly provided both nuclear weapons design and U-235.

Thus China appears wholly unwilling to adopt nonproliferation goals, that run contrary to its national interests, or the national interests of Allies that it might wish to see possessing nuclear weapons. Furthermore China is unlikely to prefer nonproliferation over national economic or energy policies. To the extent that American policy toward the thorium cycle as a proliferation issue runs contrary to Chinese trade or energy goals, China will be unwilling to give preference to American goals over its own.

Thus if American thorium related nonproliferation policies are contrary to Chinese interest, China can be expected to oppose and even undermine them. China may well regard its own internally developed LFTR as a legitimate trade item, even without proliferation controls preferred by the United States. The United States will have no choice except to adapt its nonproliferation policy to the sort of nonproliferation order that China is willing to accept. China, like India will most likely be willing to support a nonproliferation agreement that embraces thorium, but that order may be quite contrary to current US nonproliferation policy.

Thus both India and China have in the past been notably independent from American nonproliferation policies and goals, and can be expected to maintain that independence. There growing economic power will make that opposition increasingly difficult for the United States to impose its nonproliferation goals on the international community. Both India and China have interests in developing a Thorium cycle nuclear power technology, and it is very likely that any future nonproliferation order will conform to Chinese and Indian policy goals with respect to thorium fuel cycle technology.

Despite the current extremely robust growth of the Chinese economy during the last decade, some economists, looking ahead see clouds on the horizon. Michael Pettis is a professor at Peking University's Guanghua School of Management, and author of the well received book, The Volatility Machine: Emerging Economics and the Threat of Financial Collapse. Pettis is a pessimist about the stability of the international finance order, and sees international boom and bust monitary cycles effecting the economies of developing countries even more than the econmies of developed countries. In a recent article in China Financial Markets, Professor Pettis argues that

we are at the end of one of the six or so major globalization cycles that have occurred in the past two centuries. If I am right, this means that there still is a pretty significant set of major adjustments globally that have to take place before we will have reversed the most important of the many global debt and payments imbalances that have been created during the last two decades. These will be driven overall by a contraction in global liquidity, a sharply rising risk premium, substantial deleveraging, and a sharp contraction in international trade and capital imbalances.Professor Pettis predicts:

* BRICS and other developing countries have not decoupled in any meaningful sense, and once the current liquidity-driven investment boom subsides the developing world will be hit hard by the global crisis.The rest of Professor Pettis's article fleshes out his predictions about the course likely followed by the Chinese economy for the rest of the decade, and the implications of that course for Chines society, and political system. (Hat tip to Brian Wang for his recent post on Professor Pettis's economic forecast.)

* Over the next two years Chinese household consumption will continue declining as a share of GDP.

* Chinese debt levels will continue to rise quickly over the rest of this year and next.

* Chinese growth will begin to slow sharply by 2013-14 and will hit an average of 3% well before the end of the decade.

* Any decline in GDP growth will disproportionately affect investment and so the demand for non-food commodities.

* If the PBoC resists interest rate cuts as inflation declines, China may even begin slowing in 2012.

* Much slower growth in China will not lead to social unrest if China meaningfully rebalances.

* Within three years Beijing will be seriously examining large-scale privatization as part of its adjustment policy.

* European politics will continue to deteriorate rapidly and the major political parties will either become increasingly radicalized or marginalized.

* Spain and several countries, perhaps even Italy (but probably not France) will be forced to leave the euro and restructure their debt with significant debt forgiveness.

* Germany will stubbornly (and foolishly) refuse to bear its share of the burden of the European adjustment, and the subsequent retaliation by the deficit countries will cause German growth to drop to zero or negative for many years.

* Trade protection sentiment in the US will rise inexorably and unemployment stays high for a few more years.

It is my view that even if this socio-economic and political crisis strikes China, Global awareness of the grave implications of continued reliance of carbon based energy sources will rise rise rapidly. Thus at the same time China may faces an economic crisis. Even if more conventional estimates of the developmental course of turn out to be correct, China will be faced with the problem of shifting its energy system to post-carbon energy technologies.

Thus what ever the course of the Chinese economy, the need to replace energy from fossil fuel sources, with energy from post carbon sources will start to become acute within the next ten years. Thus what ever its economic situation, China will require rapidly scalable energy technologies that can replace coal and other fossil fuels. At the moment, China appears committed to developing LFTR technology. On February 2, in the wake of the Chinese LFTR announcement I stated on Nuclear Green, I stated:

The potential promise of thorium and the LFTR technology can rapidly be brought into the effort to prevent further global climate change. China, perhaps more than any other country has realized the importance of energy in increasing the wealth of its citizens, and making life for its people better. At the same time, the Chinese have paid an enormous price for their reliance on fossil fuel technology. As many as 500,000 people die every year from fossil fuel related causes. Global Warming represents another large threat to the well-being of the Chinese people, and although China has made a large commitment to renewable energy sources, the Chinese leadership is aware that renewables cannot produce anything like the amount of energy that the Chinese people need to bring their standard of living to that enjoyed by people living in advanced Industrialized and post-industrial societies. At the same time, the Chinese leadership is far more technologically oriented than the leadership of the United States or Europe.What will appeal to Chinese leadership about MSR/LFTR technology during the next decade is its potential for rapid production in large numbers and at a low cost. Uranium fueled MSRs offer a technology that is almost ready for mas production today.

Thus, the leadership of China is far more open to promising new technology. In addition China has a large thorium supply that comes from its rare earth mines, and so far has not found any use for thorium. The LFTR allows China to kill two birds with a single thorium stone. First it offers a potential source of vast amounts of environmentally clean and safe energy at a low cost, and secondly it allows China to take advantage of an unused resource, which can easily replace coal. LFTR technology has the potential of providing China with abundant energy at a very low cost, and might solidify Chinese economic, cultural and political dominance of the world for a long time to come.

The MSR core is very simple, requires few materials, and can be built with a tiny fraction of the labor required by conventional reactor cores, Other optional parts of the MSR may be more complex, but this is in no small measure because radioactive fission products can be continuously cleaned from the MSR core. The added cost of fuel salt cleaning can be balanced by a diminished cost of other safety features. Both fuel cleaning and reprocessing can be included in the MSR package. Thus the MSR can eliminate the necessity for building a separate large and complex fuel reprocessing facility. Molten Salt Reactor researchers world wide have repeatedly touted their safety. Low cost underground placement would further enhance their safety.

One the other hand the low cost of MSRs, their scalability and the sustainability of of LFTR technology would make LFTR technology an extremely valuable source of post-carbon energy, and quite possibly the dominate energy technology on earth asa soon as 2050. The paths to LFTR development were charted at Oak Ridge National Laboratory during the 1970's and are well understood. In terms of the potential cost savings that could be achieved through the adoption of LFTR technology the cost of its development would be extremely small, and indeed a number of large American companies could afford to finance LFTR development without government assistance, if they chose to do so.

Nor would MSR/LFTR development take long, if a business as usual approach were abandoned in favor if a more intensive approach. My estimate that if MSR/LFTR development were commenced in China this year, MSRs could be ready to start rolling off production lines by 2020. With factory based mass production, the replacement of carbon based electrical generation could be accomplished in a short time. In addition, to use in electrical generation, LFTRs and be used as an industrial process heat source. They can be used to produce hydrogen, and carbon based liquid fuels from atmospheric CO2 and water. They can also be used to power ships.

The principle obstacle to MSR/LFTR development is ignorance and human incredulity. Until recently Molten Salt Reactor technology was not even be mentioned is the training of reactor physicists and nuclear engineers. Past statements about Molten Salt Reactor technology form the Department of Energy are filled with misinformation While Secretary of Energy Chu recently made statements about the LFTR that suggest he had been given the same misinformation. Even when informed about the potential some people are incredulous, or insist that it would take to long to develop to be a practical solution, or that it is too technologically challenging. The Chinese have a significant advantage, because its technologically sophisticated national leadership is aware of the potential that the LFTR offers.

The LFTR approach to world energy issues amounts to a paradigm shift. What will be required for the success of a LFTR based approach is the spread of knowledge about the LFTR and of a vision of LFTR potential. Knowledge and vision cannot simply be spread by policy, and indeed in the United States policy has been an impediment to its spread, until the policy makers themselves are educated, and catch a little of the vision. Once that knowledge and the vision are discovered by enough people, as appears to be the case in China, a tsunami of change will follow that will rapidly sweep us forward into the post carbon age.

Thus by continuing its commitment to develop LFTR technology, Chinese leadership, either Communist or democratic, will almost certainly assure continued Chinese economic development, whatever short run national economic problems emerge in China.

Thus by continuing its commitment to develop LFTR technology, Chinese leadership, either Communist or democratic, will almost certainly assure continued Chinese economic development, whatever short run national economic problems emerge in China.

Historically China has been economically self contained, and although Chinese economic development has focused on international trade, Professor Pettis offers the view that future Chinese economic development will focuse on the growth of internal markets. In addition the Chinese government is under great though largely hidden pressures to clean up environmental problems. Shifting from coal to Thorium would solve serveral environmental problems at the same time. A shife from trade to internal economic grown and increasingf environmental concerns thus point to a rational for thorium energy use as a matter of national policy.

The historic foreign policy of China has usually been to exercise hegemony over its neighbors but to not incorporate them into its empire. In addition, the Chines state has usually defended its territory rather than sought expansion. The present Communist government has acted to insure that traditional Chinese imperial territory remain part of China. The 1949 invasion of Tibet, and the continued Chinese insistence that Taiwan is part of China are evidence of that poi icy, The Chinese Government is also concerned about border defenses, and the 1962 war between China and India was motivated by Chinese desires to obtain defensible southern borders.

Finally China has cooperated with American Nonproliferation policies only when it is in Chinese interests to do so. China has in the past been willing to transfer of nuclear weapons technology and even weapons grade nuclear materials, when the development of nuclear weapons by other states furthered what Chinese leaders viewed as China's national interest. China has viewed India as a potential enemy, and thus its allied itself with another enemy of India Pakistan. China reportedly provided both nuclear weapons design and U-235.

Thus China appears wholly unwilling to adopt nonproliferation goals, that run contrary to its national interests, or the national interests of Allies that it might wish to see possessing nuclear weapons. Furthermore China is unlikely to prefer nonproliferation over national economic or energy policies. To the extent that American policy toward the thorium cycle as a proliferation issue runs contrary to Chinese trade or energy goals, China will be unwilling to give preference to American goals over its own.

Thus if American thorium related nonproliferation policies are contrary to Chinese interest, China can be expected to oppose and even undermine them. China may well regard its own internally developed LFTR as a legitimate trade item, even without proliferation controls preferred by the United States. The United States will have no choice except to adapt its nonproliferation policy to the sort of nonproliferation order that China is willing to accept. China, like India will most likely be willing to support a nonproliferation agreement that embraces thorium, but that order may be quite contrary to current US nonproliferation policy.

Thus both India and China have in the past been notably independent from American nonproliferation policies and goals, and can be expected to maintain that independence. There growing economic power will make that opposition increasingly difficult for the United States to impose its nonproliferation goals on the international community. Both India and China have interests in developing a Thorium cycle nuclear power technology, and it is very likely that any future nonproliferation order will conform to Chinese and Indian policy goals with respect to thorium fuel cycle technology.

Labels:

China,

LFTRs,

MSRs,

non proliferation,

Thorium

Friday, August 12, 2011

The D A Ryan MSR/LFTR critique: Not ready for Prime Time, Part II

Several weeks ago, I posted a a critical review of DA Ryan's discussion of Molten Salt Reactor technology. Ryan is a British engineer, but his assessment did not appear to be at all well informed. Ryan began with questionable assumptions, failed to note well regarded information sources that simply disagreed with his controversial views, then proceeded to reason from unsupported assumptions to dogmatic conclusions about nuclear energy.

I generally judge how well a writer is doing by picking out an issue I am familiar with and looking at how well he treats that issue. In my review of Ryan, I looked at his assertion that there was graphite fires risk in Molten Salt Reactors. Ryan saw the fire risk ans a major hazard and claimed, “graphite is basically just high grade coal.” This is nonsense. Not only is graphite not vert flamible, but graphite powder based fire extinguishers are used to fight fires in metals like lithium. In addition, Post-Chernobyl studies attempting to assess graphite fire dangers as nuclear safety issues, have concluded that fires in graphite moderated reactors were much less likely than previously believed. Ryan insists that the fire in the Windscape unit 1 reactor, was a graphite fire. However recent remote visual inspections of the Windscale reactor demonstrate that very little fire related damage to its graphite structures occurred. This is wholly inconsistent with Ryan's contention, but in the face of this strong evidence, he refuses to acknowledge the weakness of the Windscale graphite fire contention, or the unlikelihood of a graphite fire in a Molten Salt Reactor. This behavior might be referred to as dogmatically clinging to a mistaken assumption after the assumption has been demonstrated to be false.

Bill Hannahan also posted several critical comments on Ryan's MSR critique. Bill has graciously offered to pass on his comments on Nuclear Green, and although delayed by my recent surgery, here they are.

The D A Ryan MSR/LFTR critique: Not ready for Prime Time, Part II

By Bill Hannahan

Charles Barton published an essay about a nuclear energy review that contained a chapter highly critical of Molten Salt Reactor technology. I began submitting review comments on each section of that chapter. After several comments were posted my comments were blocked. Charles has graciously offered to publish all the comments.

REVIEW COMMENTS ON 8.2 The MSRE experiment

“Notably, it never generated a single watt of electricity. As I’ve mentioned previously the turbo generator systems for high temperature reactors is technically challenging, especially for the LFTR as the molten salt presents a number of design challenges….

That said, the goal of the MSR experiment was to prove the reactor concept, not develop turbo machinery kit, which would have been a serious (and costly) distraction.”

The Author effectively counters his own point. When GE builds a new jet engine they do not build a new plane to test it on. They test it on a stand. Then they test it on an OLD plane with other well proven engines. After the new design has met its performance requirements it is mated with the new airframe for which it was designed. We know how to convert high temperature heat into electric power.

Checking the author’s link to part 3 to review the technical challenges for LFTR we find this;

“Several of these proposed reactors have operating temperatures in excess of +800 °C. Some, such as the LFTR would need critical parts to go even higher as much as +1,600 °C…

So before we even begin our evaluation, we have to conclude that a big stumbling block to several of the proposed reactor designs is this issue of materials choice.”

One of the great advantages of the MSR is the ability to go to high temperature without pressurization, thereby allowing higher thermal efficiency and reducing component size. The author is trying to make a silk purse look like a sow’s ear.

The most important quality in an engineer is the ability to compromise wisely. Engineers are trying to create the optimum balance over many issues, construction cost, life expectancy, efficiency, safety, maintainability, operating and maintenance cost etc. The engineer who focuses on one parameter at the expense of all others will design a failure.

The author makes it sound as if these issues only apply to the MSR, but all engineering is like that, the Chevy volt, Apple I pad, Boeing 787 etc. are all compromises.

Imagine doing the engineering for a solar thermal plant with molten salt storage. Some collectors may be a mile away from the storage facility. They go from blazing hot temperatures at high noon to freezing temperatures on some nights. The salt temperature is constantly changing throughout the cycle, flow rates are constantly being adjusted as temperatures change, to maintain the desired output. Heat exchangers, piping and storage vessels have to be extra large to envelope worst case conditions.

The constant steady flow of clean high temperature intermediate loop salt into the steam generator of an MSR makes the design of those components a breeze by comparison.

It is likely that the parametric studies will show that the first generation MSR’s should be simple uranium burning reactors made of familiar materials, operating at the low end of the MSR potential temperature range.

We must pay for the R&D to do the studies and build a few plants to get the engineering data. That is how we make progress. That is how we develop systems that can make energy cheaper than fossil fuel and end the age of fossil fuel.

“Stories of said pipe work glowing red (see below) are worrying, as it indicates they were operating well within the thermal creep zone... Consequently, its unlikely one could utilise the same design spec today for a commercial plant.”

Yes, the design engineers will have to do some engineering to ensure that all materials are operating well within their nominal performance envelope. Nothing unusual about that.

“Also, the MSRE never included the more tricky Chemical Processing Plant. One was designed by ORNL but never installed.”

Right. This is why I think the first generation MSR will be the simple uranium burner that does not need on line processing. We do not need breeders immediately.

http://www.youtube.com/watch?v=8F0tUDJ35So

http://www.thoriumenergyalliance.com/downloads/TEAC3%20presentations/TEAC3_LeBlanc_David.pdf

The general tone seems to be that the MSR is not mature fully developed technology; therefore we should not pursue it. If humans had taken that view throughout history we would still be living in caves.

Review of 8.3 Thorium Cycle questions and problems

“we’ll still need supplies of Uranium to get Thorium reactors going again whenever we have to turn it off (which will happen at least once a year or so during its annual maintenance shutdown)…

Obviously, once we exhaust the world’s U-235 stockpiles, LFTR’s and any other Thorium fuelled reactors will cease to function.”

For the LFTR you would only need uranium 235 to startup and breed the uranium 233 sufficient to continue operation. No additional uranium is needed for each shutsown/startup cycle.

There are 3.5 billion tons of uranium in seawater. Perhaps half of that is available at less than 5 times today’s price. That’s still cheap for conventional reactors that require 58 pounds of uranium to generate an 80 year lifetime supply of electricity for one American. It is very cheap for uranium MSR's that requires only 12 pounds of uranium to generate a lifetime supply of electricity for one American, and it is an insignificant cost in a breeder reactor that uses 6 ounces of uranium and/or thorium per lifetime supply of electricity.

“Thorium-232 is a problem with its half life of 14 Billion years (and while the T-232 isn’t a major worry its only mildly radioactive, all the time during this 14 Billion years it will be decaying and producing stuff that is!).”

Thorium-232 (natural thorium) is now scattered throughout the earths crust, including under your house and mine. So removing it, and converting it to fission products that loose the vast majority of their activity in a few hundred years, while extracting enormous quantities of emission free energy, and placing those fission products in a carefully selected location deep under ground or under the seabed, is a good idea.

Nuclear power means earth will be LESS radioactive for most of its remaining years than it would have been without humans.

Comments on 8.4 The Chemical Seperation Plant and waste output

“One other misconception on the internet is the view that a LFTR reactor will produce almost no nuclear waste”

It depends on your definition of almost. To generate an 80 year lifetime supply of electricity for one person in the U.S. with coal we burn 1,140,000 pounds of coal, producing 2,440,000 pounds of CO2 and thousands of pounds of toxic waste, much of it released into the atmosphere.

To generate a lifetime supply of electricity with today’s reactors we mine about 58 pounds of uranium of which about 10 pounds gets into the reactor and produces 6 ounces of fission products. With breeder reactors we mine 6 ounces of uranium or thorium to do the same thing.

The complete natural decay of one uranium atom to one stable atom of lead produces about 7 times more radiation than the complete decay of the fission products from one uranium atom. Uranium and thorium are nature’s radioactive waste, distributed throughout the earths crust without special containment vessels. Nature’s radioactive waste is not buried in carefully selected sites deep underground, it can often be found in soil on the surface.

The extraction of uranium from sea water has been demonstrated at an estimated cost of $160/kg.

http://nextbigfuture.com/2007/11/two-proposals-for-mining-ocean-for-720.html

Coal, our cheapest fossil fuel, costs 3.2 cents / kWh.

http://www.eia.gov/cneaf/electricity/epa/epat8p2.html

We generate about 1,500 watts per person in the U.S., so an 80 year lifetime supply of electricity is about 1,000,000 kWh's. Lifetime fuel cost with coal is $34,000, $424/year.

A LFTR will consume 6 ounces of fuel to make this much electricity. To be conservative lets assume that the uranium required to start the reactor is 10% of the lifetime reactor fuel consumption (it’s probably more like 1%, even less considering that at end of life the uranium 233 can be transferred into a new reactor).

Some fission products have positive value.

http://www.youtube.com/watch?v=rv-mFSoZOkE

By destroying 6 ounces of uranium we make earth LESS radioactive for most of its remaining years than it would have been without humans, we prevent the formation of six ounces of lead that would be toxic forever, we produce some valuable material, we produce a lifetime supply of electricity, and we prevent the harmful effects of generating that energy by some other means.

In my opinion any technology that destroys more waste than it produces meets this requirement; “will produce almost no nuclear waste”

“I’ve seen various dusty line drawings of the 1970’s ORNL proposal, you can see them yourself here and here, but that’s it. I would firstly note that materials science and chemical processing technology has moved on hugely in the last 40 years, so I doubt it would be sensible to build an CPP as shown in these plans. A new one would have to be redesigned from scratch.”

I agree with everything except “from scratch.” It makes no sense to ignore the knowledge and experience gained in the past. We should build on that.

“Either way building our entire energy strategy on a as of yet unproven concept would be dangerous. The same equally goes for Thorium.”

I agree, it is foolish to spend billions building huge numbers of windmills and solar farms that cannot produce reliable dispatchable kWh's. That is why I recommend an all out R&D program to develop all possible replacements for fossil fuel.

http://www.theoildrum.com/node/7275#comment-755200

Comments on 8.5 Graphite core and Fire Risk

“Graphite is basically ultra high grade coal!” …

The Windscale reactor is basically a stovepipe charcoal starter with forced air ventilation, scaled up to the size of a power plant. If the designers had actually used coal as a moderator it would have fired up like a blast furnace. It would have destroyed the vent filters, vaporized much of the fuel and likely collapsed the building.

“Inspections have shown that there was NOT a graphite fire: damage to graphite, caused by severely overheated fuel assemblies, was localised.”

http://www.hse.gov.uk/aboutus/meetings/iacs/nusac/131005/p18.pdf

Graphite clearly does not burn like coal. The claim that, “Graphite is basically ultra high grade coal!”, is either based on lack of knowledge or it is deliberate disinformation.

The author acknowledges that in a MSR the graphite will normally be submerged in molten salt, not air. The dump tank will be filled with an inert gas. When the core is dumped, a vent line from the top of the dump tank to the top of the reactor vessel will transfer the inert gas into the reactor vessel. The reactor room will likely be inerted as well.

For air to get to the graphite the salt must be dumped and at least two barriers must be breached, and there will be no fans to generate a high flow rate.

If the graphite did somehow burn, recall that the vast majority of fission products would be safely tucked away down below in the dump tanks, or previously removed to safe storage. Only a thin patina of fission products on the graphite would be subject to fire, not enough to support a big release.

The claim that a graphite fire in a MSR could result in a large release of fission products is a groundless fabrication with no supporting evidence and no potential mechanism.

A 50 year follow up of Windscale workers showed;

“Despite the higher doses received by the fire cohort workers the SMRs by decade for all malignant cancer are consistently lower than those of the non-fire cohort workers.”

http://iopscience.iop.org/0952-4746/30/3/001/pdf/0952-4746_30_3_001.pdf

Comments on 8.6 Why air cooling a LFTR would be a very bad idea

“Another misconception is that LFTR’s can be air-cooled (here and here) rather than being dependant on the water cooling process we utilise in most other power stations.”

Actually the high temperature of MSR’s makes them ideally suited for dry cooling in arid climates.

“Firstly, fire safety, air is an oxidising substance. Fires start all the time at power stations (fossil fuel fired and nuclear ones), especially in the turbine halls and the last thing we want in an emergency is a load of big cooling fans blasting in air and literally fanning the flames!”

I think the author has since acknowledged that the fans would be cooling the condensers located outside the turbine hall, not in the turbine hall or containment building. The turbine hall is separate from the reactor containment and its safety related equipment.

“In this scenario we’d face the dilemma between stopping the fans and cutting of the source of cooling”

The steam plant and its condenser are not safety related systems, the reactor does not rely on the steam plant for safe cooling. Decay heat will be removed by natural convection of air or water. There are no flammable materials in or around the dump tanks.

“The Uranium we’re mining was safe underground and seperate from the biosphere.”

According to the EPA, thousands die from radon exposure every year in the U.S. alone. Nuclear power is far safer than natural uranium left in the ground.

““basically high grade coal” was a quip”

Publishing a quip that you know is misleading and prejudicial is unethical.

The danger of a positive void coefficient of reactivity was well known before the Chernobyl reactors were built. The design could never have been approved for construction in the west, nor could any power reactor design without a containment building, as Chernobyl was. Operators bypassed the protection systems and violated the operating limits to perform a dangerous experiment and spiked the power to 100 times design limits resulting in a steam explosion that blew the reactor apart.

The risk of hydrogen production from the zirconium water reaction was well known, as are the mitigating mechanisms; ventilation to keep concentration below the flammability limit or ignition to burn the hydrogen as it is produced to avoid an explosion. Unfortunately the Japanese failed to deal adequately with the hydrogen production.

The only nuclear accidents to release large quantities of fission products are those where a direct path to the atmosphere is provided by design or by explosion. Even then it is interesting that out of hundreds of fission products, only a few of the most volatile constitute most of the risk.

MSR's have continuous online refueling. There is only enough reactivity for normal operation. I do not know of any way to make an MSR explode. Do you?

Cesium is by far the most problematic fission product in an accident. It melts at 28C, the boiling point is 671 C. When a cesium atom is produced in a MSR it immediately hooks up with a fluorine atom to make cesium fluoride, melting point 682C, boiling point 1251 C, so it has much lower volatility resulting in greatly reduced emissions under accident conditions. Jet fuel boils at about 200 C, and the temperature of burning jet fuel is 260-315C in open air, 980 C in an ideal burner.

http://en.wikipedia.org/wiki/Jet_fuel

You could cool a MSR by spraying it with burning jet fuel.

““the fuel will be safely tucked away in dumb tanks” IF the fuel dump process goes okay! This is the danger here, you’re relying on the successful functioning of your fuel dump process”

If the fuel is not dumped the graphite is submerged in salt, no oxygen contact, no fire. You might say, ‘what if it is half submerged?’ In that case the fission products are mostly below the liquid line. If the graphite above the liquid line burns, very little fission product will be volatilized, and it will plate out as soon as it contacts a cooler surface.

This is a fundamental difference between solid and liquid fueled reactors. Volatile fission products will be removed continuously and non volatile products will largely stay on site during an accident. The author cannot have it both ways; he provides no evidence or mechanism to support the idea that a graphite fire in a MSR can happen, and even if it does burn, no mechanism that would result in a large release of radioactivity. The graphite fire hazard claim with MSR's is a groundless fabrication.

“Defence in depth would require that other measures be taken also, although this could be as simple as just putting it all in a reinforced concrete building designed to withstand a high temperature fire.”

I have no doubt that all future power reactors, including MSR's, will have a robust containment. But the MSR containment can be much smaller, using far less material, because hi temperature heat exchangers are very small and steam generators can be small and located outside containment. A pipe rupture inside containment will not release a huge volume of gas or steam, so no need for a large expensive high pressure containment vessel.

“you still need some water on site”

There will be water on site, but you do not need it to keep MSR fuel safe. Engines and motors are air cooled. Light bulbs with white hot filaments are air cooled. In fact, the hotter an object runs, the easier it is to air cool, another big advantage of MSR's.

“So all in all I’d argue uranium mining causes as many (if not more) problems than it solves.”

If we replaced all coal plants with nuclear plants, eliminating mountain top removal, huge releases of mercury, cadmium, soot, CO2 etc that would save perhaps 1,000,000 lives per year and prevent millions more non fatal adverse health effects. How will uranium mining match those effects, especially with advanced designs that reduce mining to 6 ounces per lifetime?

FOLLOWUP on sea water uranium comment by bluerock.

“Extracting uranium from the sea is not a practical possibility.”

If Bardi is right why can’t he answer questions? Why can’t he find the error in contrary analysis? What is your answer to these questions?

http://europe.theoildrum.com/node/4558#comment-412498

http://europe.theoildrum.com/node/4558#comment-412127

http://europe.theoildrum.com/node/4558#comment-413193

http://europe.theoildrum.com/node/4558#comment-414051

http://europe.theoildrum.com/node/4558#comment-415226

“Maybe, like me, he can’t be bothered to read, research and respond to every challenge that appears on the interwebs.”

It is interesting that he found time to address the easy and favorable comments but not the hard questions based on facts and logic.

“Here’s one way to shut us all up: prove that it is technically and *economically* viable to extract uranium from seawater at quantities that could supply a global nuclear industry.”

Had you carefully reviewed your own reference you would know that I addressed that point.

“Why are there no sea water uranium extraction plants?

Historically the price has been under $60 / pound with a few big spikes.

Would you bet your life savings on uranium staying above $200 / lb? I don’t think so, and neither do professional investors, however if sea water technology keeps improving the cost may drop enough to make it happen sooner than most people think.

Sea water uranium is very important because it puts a cap of $200/pound on the maximum sustainable cost of uranium for thousands of years.

Sea water uranium does not have to supply all of our uranium in order to cap the uranium price at $200/pound. It only has to replace the percentage of land based uranium sources that cost more than $200/pound, and that percentage is zero for the foreseeable future.”

http://europe.theoildrum.com/node/4558#comment-413193

Comments on 8.7 Why power cycling a LFTR would be an even worse idea!

“The truth is that the LFTR is as constrained in it power output capabilities as other reactors, possibly more constrained in fact.”

It is interesting that you know the performance specifications of power plants that have not even been designed yet.

“Power cycling a LFTR would necessitate such cycles, worsening our already narrow materials choice and requiring a much more heavily constructed reactor.”

So you have already designed the plant, chosen the materials, selected the salt formula, determined the operating temperature. Sounds like you designed a poor reactor.

“It is also worth noting that existing nuclear stations are capable of some level of power cycling anyway just not much!”

The most popular gen. III reactor is the AP-1000. Its design includes the lessons learned from decades of experience running gen. II reactors. Look at its capability.

“The AP1000 is designed to withstand the following operational occurrences without the generation of a reactor trip or actuation of the safety related passive engineered safety systems. The logic and setpoints for the AP1000 Nuclear Steam Supply System (NSSS) control systems are developed in order to meet the following operational transients without reaching any of the protection system setpoints.

· ± 5%/minute ramp load change within 15% and 100% power

· ± 10% step load change within 15% and 100% power

· 100% generator load rejection

· 100-50-100% power level daily load follow over 90% of the fuel cycle life

· Grid frequency changes equivalent to 10% peak-to-peak power changes at 2%/minute rate

· 20% power step increase or decrease within 10 minutes

· Loss of a single feedwater pump

Off-site power has no safety-related function due to the passive safety features incorporated in the AP1000 design. Therefore, redundant off-site power supplies are not required

Containing Core Damage. The AP1000 design provides the operators with the ability to drain the IRWST water into the reactor cavity in the event that the core has uncovered and is melting. This prevents reactor vessel failure and subsequent relocation of molten core debris into the containment. Retention of the debris in the vessel significantly reduces the uncertainty in the assessment of containment failure and radioactive release to the environment due to ex-vessel severe accident phenomena.”

http://www.ne.doe.gov/pdfFiles/AP1000_Plant_Description.pdf

“The turbine generator is intended not only for base load operation, but also for load follow capability. Mechanical design of the turbine root and rotor steeple attachments uses optimized contour to significantly reduce operational stresses.”

https://www.ukap1000application.com/PDFDocs/Safety/UKP-GW-GL-740%20Rev%200.pdf

As implied above, load following thermal/mechanical stress cycles are largely limited to the steam turbine. If MSR designers want to keep reactor temperature constant, they can coordinate feedwater flow to the steam generators with reactor power to maintain constant reactor average temperature over the full range of operation.

As power is reduced the reactor hot leg temperature will cool slightly and the cold leg temperature will warm slightly, keeping the average constant. If the engineers want to eliminate even that small temperature swing they can modulate salt flow rate with power to keep the inlet and outlet temperatures constant over the full range of operation.

Six ounces of thorium can produce an 80 year lifetime supply of electricity in a LFTR. It requires no enrichment or fabrication into fuel rods. Assuming the fuel is free will induce a negligible error in the overall economic analysis.

These plants can be run a few percent over demand with fine control managed by dumping excess power into a resistor bank. This would allow near instant slew rates without subjecting the plant to rapid power jockeying. The grid itself could be used as the resistor bank by modulating power factor. With fuel cost essentially zero, they could run the plants continuously at 100% and avoid any thermal cycling of the steam turbine/generator, using the excess power to make hydrogen or carbon based fuel from atmospheric CO2.

http://www.lanl.gov/news/newsbulletin/pdf/Green_Freedom_Overview.pdf

As electric vehicles become more numerous, nighttime charging and smart grid technology will level out the day/night swings.

The addition of intermittent, unreliable, undispatchable wind and solar farms has made load balancing much more difficult.

“- the combination of wind facilities +balancing facilities is significantly less economical than using the balancing facility at rated output in base-loaded mode.”

http://theenergycollective.com/willem-post/57905/wind-power-and-co2-emissions

High variability induced by wind and solar farms may cancel all claimed emissions reductions.

http://www.bizjournals.com/denver/stories/2010/04/19/daily11.html

Intermittent, unreliable, undispatchable energy sources must be backed up by reliable dispatchable plants. The true value of intermittent, unreliable, undispatchable kWh's is the cost of fuel saved, 0.5 cents/kWh nuclear, 3.2 cents/kWh coal and 5.2 cents/kWh gas. The simplest non breeder uranium MSR would have a fuel cost of 0.1 cents/kWh, essentially zero for breeders.

The real reason nuclear plants do not load follow is that they have the lowest fuel cost. Intermittent, unreliable, undispatchable wind and solar kWh's would have no value on a nuclear powered grid.

“Several meltdowns of liquid metal cooled reactors have resulted from such clogging incidents.”

A sodium cooled experimental reactor with solid metal fuel and a serious design defect has little relevance to future MSR's.

Comments on 8.8 Thermal windows and material choices

This entire section boils down to “Some R&D is required.” No one denies that. There is no reason to believe that any of the issues mentioned are show stoppers.

Comments on 8.9 The Brayton cycle and MSR reactors

The Wright Brothers did not build an SR-71. Henry Ford did not start with the GT-40. Like all technologies, the MSR will start simple and build on that experience.

“the fact that our turbine would have to be designed to withstand having a mixture of molten salt and fluorided fuel passed through it at very high temperatures.”

There would be an intermediate heat exchanger, no fission products outside containment.

“oh! but we almost forgot about that chemical processing plant and its net energy inputs, say we deduct 5-10% of reactor power output to account for running that,”

6 ounces of thorium can produce about 1,000,000 kWh's. So processing 6 ounces of fission products requires 100,000 kWh's? Not a chance.

Comments on 8.10 Piping, FMEA and leak prevention

“the major risk to any MSR reactor is ….either a fire effecting its graphite core (which for a LF reactors running at low vapour pressure is a greater risk than with any other graphite cored reactor) or more likely a burst pipe.”

The fire risk was covered in a previous section.

“the major danger with a LF plant is that somewhere in the lengthy network of pipes that it and its CPP consist of, something breaks.”

The author carefully avoids describing the exact sequence of events that results in a large scale release of fission products to the atmosphere that he alludes to.

There is a strong incentive to minimize fuel volume. Therefore the intermediate heat exchangers will be close to the reactor vessel to keep pipe length short.

Small leaks will solidify on the floor. Large leaks will flow to the drain tanks. There is no large inventory of volatile fission products. There is no mechanism for a powerful explosion. The reactor room will be inerted.

During normal operations volatile fission products will bubble out of the hot salt as they are formed and be converted to a form that is non volatile and easy to store away from the reactor. Fission produces that do not come out of the molten salt are in forms that are stable at very high temperature. So there will be no inventory of volatile fission products available for release in an accident, as can happen when solid fuel melts under accident conditions.

So what is the detailed scenario resulting in a large scale release of fission products to the countryside? What is the chemical composition of the fission products? What are the melting and boiling temperatures of those compounds? What mechanism drives them out of the plant into the atmosphere?

By what path do they escape?

“Take for example the pipe at the base of the reactor that allows us to dump the core to the emergency dump tanks… suppose for example that it bursts during a dump scenario? Obviously we need a containment vessel around the pipe to catch any leaks.”

The answer is in the drawing of the FUJI MSR in your report. The spill would flow down the floor drain into the emergency drain tank.

“Also simply relying on gravity would be inadequate in certain scenarios, a pump on a separate stem (or a tank of inert high pressure gas connected up to the pressure vessel to “encourage” the fuel to drain away), would be necessary.”

Gravity has not failed in 14 billion years. Describe in detail an accident sequence of events where the proposed additional equipment would prevent a large offsite release of fission products that could not be prevented without that extra equipment.

“But what if the trigger for the accident is a clogging of fuel channels (as discussed earlier) by solidified fuel?”

The solidified fuel would heat up and re-melt.

“If we dump in that scenario we might cause the dump pipe to clog also, likely leading to a criticality incident or its failure and a breach.”

Maintaining criticality under normal operation with the minimum concentration of fissile material is the challenge. The poor geometry and lack of moderation in a spill avoids criticality problems.

“So we would need a thermal regulation system around the pipe to ensure it can be heated or cooled as necessary. Also I don’t like the idea behind this “freeze plug”. I realise the passive safety benefits it brings, but it’s just going to be too slow to act in a real emergency and there’s too much that can go wrong with it. If I were an engineer at such a plant I’d want a big shiny red “dump core now!” panic button on my control panel.”

I agree. I have never felt good about the fan cooled freeze plug.

If I were responsible for this part of the plant I would ask a dozen bright engineers to independently come up with a plan for handling this safety function, then pass them around and generate lists of pros and cons for each.

My suggestion would be to use a thermal rupture disk, or a flapper valve held shut by a thermal fuse or electromagnet. In each case there would be the option for quick manual operation. There would be an orifice to allow a continuous metered flow of salt into the drain tank. That flow would maintain the temperature of the drain line and verify its functional availability. The salt stream would be continuously pumped back into the primary loop. It could also be the source of fuel for continuous chemical processing.

There would also be another dump path with a conventional control valve; it would be the primary valve, the thermal device would be the backup, along with the floor drain.

In the extremely unlikely situation where everything fails the stockholders are going to take a hit, but there will be no major release of fission products to the countryside.

“see how in the process of getting one short section of pipe back to within a reasonable safety margin the result has been for it to balloon into a massively complex system in the space of 5 minutes.”

Welcome to the real world of engineering. All large scale power plants are complicated. A Boeing 787 is more complicated then a Cessna 150. MSR's can be much smaller and less complicated than coal plants with emissions controls of the same output.

“the benefits of a Molten-Salt fuel system are outweighted by the lengthy inspection process of all that pipe work.”

The compact design of the MSR allowed by high temperature and lack of active safety systems and complicated emission control systems makes the piping far less complex and easier to inspect than a conventional coal or nuclear plant.

The failure of that piping would be less dangerous than the failure of fuel system piping at a natural gas plant.

“any MSR reactor would inevitably have to have large stockpiles of salt stored on site or nearby,”

Why? Small amounts of material are coming out of the system; why/how would we put in large amounts of additional material?

“Fluorine gas is extremely toxic (several times more deadly than chlorine”

Toxicity Data, Fluorine

LC50 inhal (rat)

185 ppm (300 mg/m3; 1 h)

Toxicity Data, Chlorine

LC50 inhal (rat)

293 ppm (879 mg/m3; 1 h)

http://www.nap.edu/openbook.php?record_id=4911&page=320

By volume fluorine is less than twice as toxic as chlorine. The U.S. consumes ten billion kg of chlorine each year; enough to kill every man woman and child in the U.S. every 45 minutes. Essentially all of that is manufactured and consumed under conditions less secure than those inside a reactor containment building.

Fluorine will not be stored or transported in elemental form in large quantities. The chemical processing equipment in LFTR's will be very small by industrial standards, and they will be among the most secure and well regulated in the world.

“ Another misconception of the LFTR fans is that LFTR’s will not require the same large exclusion zones as other reactors. A.”

Other reactors do not have large exclusion zones, nor will LFTR's. Check Google Earth.

“A LFTR is essentially just a glorified chemical plant”

A large LFTR will produce a few pounds of fission products per day. The image of a large industrial chemical plant is false. Many common industrial facilities use far larger quantities of hazardous materials under far less secure conditions.

I expect the chemical processing will be done in sealed tamper resistant modules with standardized size and simple connections so that as processing technology improves, the older plants can have access to the latest technology.

8.11 MSR’s, A proliferate problem?

There are two relatively easy, fast, cheap paths to nuclear explosives;

1... Extraction of U235 from natural or reactor grade uranium. (enrichment technology).

2... Plutonium production using a simple unpressurized water cooled graphite reactor with natural uranium fuel.

There is at least one difficult, time consuming, and expensive path to nuclear explosives; using a commercial nuclear power plant.

If a group or nation wants to build nuclear explosives, the optimum level of proliferation resistance is that which is just barely easy enough to convince them to take the most difficult, time consuming, and expensive path to nuclear explosives.

All proposed future reactor designs are far beyond this standard, so it makes no sense to add complexity and cost to a plant design in response to the proliferation issue. That just makes it harder to build new energy sources that are much cheaper than burning fossil fuel, and there in lies a real risk.

The solution to the proliferation issue is education.

8.13 LFTR, the Kool-Aid Fuelled Reactor?