There are eight primary sources of nuclear costs:

The cost of the land upon which the nuclear power plant (NPP) is built.

Costs related to designing the NPP

Cost related to the materials from which the NPP is built.

Labor costs related to manufacture and construction.

The cost of obtaining regulatory approval

Investment related costs (interest, etc.)

Transportation and Access related costs

The cost of the electrical transmission system that connects the NPP to the grid

Any attempt to lower nuclear costs must find a way to lower the cost of one or more of these.

Land related costs can be lowered if the investor already owns the land. In the case of NPPs, land costs can be lowered if the NPP is built on a preexisting NPP site. Other, for example transportation related investments may not be required, and access to water is very likely to be available. NPPs can also be located on the site of obsolete coal fired power plants slated to be shut down for technological or environmental reasons. The same advantages of the NPP location would apply to the coal powered site, and additional facilities – for example the turbine hall, parking lots, administrative buildings, workshops, transformer farms, etc. - can potentially be recycled. The layout and size o an existing coal fired power plant may not be appropriate for adaptation for a large nuclear plant, but a cluster of small reactor approach would allow for far greater flexibility in facility layout, and would be far more easy to accommodate.

Small reactors, especially advanced technology small reactors, offer advancements is siting flexibility. For example, clusters of small reactors can be located in former salt mines.

Serial production lowers design costs. Design costs are largely fixed. Design costs can be divided among all of the units produced. If one reactor of a particular design is produced, then the recovery of the cost of that design would be through sale of that unit. If hundreds of units are produced, the recovery of the design cost can be divided between all of the units.

Finally, design simplification can lower nuclear coss. The Generation IV Molten Salt Reactor design offers revolutionary design simplification. In the Molten Salt Reactor the fuel is dissolved in the coolant. Thus much of the core structure is eliminated. Because the Molten Salt Reactor features a negative coefficient of reactivity, the reactor is highly stable without operator control input. Control rods can be partially or completely eliminated. These simple features lower manufacturing costs. And lesson manufacturing time.

The material input into a NPP per watt of output typically decreases as total reactor output rises. Traditionally this has lead to the economies of scales argument, which maintains that the larger the reactor output, the lower the per watt cost. There are, however, problems with this assessment. While it is true that larger size usually means lower material costs per unit of electrical output, there are exceptions to this rule, especially with respect to advanced nuclear technology.

For example:

The greater thermal efficiency of a reactor of similar core size might lower output cost per unit of heat, compared to that of a similar sized, but efficient design.

Reactor safety issues may effect materials input. Light Water Reactor cores and heat exchanges operate under very high pressure. They require significant amounts of material to prevent steam explosions. LWR outer containment structures are typically massive, and thus require large

A more compact reactor core may lower material requirements. Thus if two reactors have the same output, the one with the smaller core is likely to require fewer materials.

Underground reactor siting could potentially lower reactor structural costs, by offering protection against terrorist attacks from aircraft and at surface levels with lower materials inputs.

Small generation componants can lower material requirements. Thus supercitical carbon dioxide turbines are much smaller than steam turbines used in convential reactors. Small turbines require fewer materials, and can be housed in smaller turbine halls, which in turn require less material and labor input to build.

Thus a small advanced technology reactor with a compact core and high thermal efficiency, that operates at a one atmosphere pressure level, and can be sited underground might require fewer materials inputs per unit of electrical output than a much larger conventional reactor.

In addition manufacturing costs can be lowered by simplifying reactor design. Passive safety features can in some instances lower nuclear costs. For example thermosyphoning of reactor coolant, may save the cost of manufacturing and installing coolant punps. Gravity feed emergancy coolant systems save on manufacturing costs in several ways, They do not require backup generators or pumps, thus many of the expenses of older emergancy coolant sysyems can be saved.

Labor costs can be lowered by shifting work from the field to a factory. The more labor which can be performed in a factory, the lower the over all costs. Modular production is consistent with factory manufacture. Factory manufacture lowers labor costs in several ways. First serial production leads to the division of labor, which in turn typically increases labor productivity. The division of labor decreases the skill set required from individual workers. Decreased labor skill sets decrease labor wage expectations. Factory work settings, as opposed to field work settings also decrease wage expectations.

Thus serial production of small reactors in factories would tend to lower labor costs of nuclear manufacture.

The current nuclear regulatory environment favor serial manufacture. Once an example of a particular nuclear design is approved by the NRC is approved, the approval of all subsequent reactors using the design is automatic. Environmental aspects of subsequent application, however, receive the same attention, since they varie from facility to facility.

In addition to NRC license requirements, other licenses may be required. For example, the use of cooling water from rivers and lakes is not automatic, and usually requires regulatory approval. One of the advantages of recycling coal fired power plant sites, is that water access permits may already exist, and potentially can be transferred.

But what if obtaining a water use permit is not possible? With small reactor designs air rather water cooling is practical, with relatively modest efficiency penalties. With efficient advanced reactors, the efficiency benefits may far outweigh the efficiency losses related to air cooling.

Interest accrues as nuclear power plant construction, and accrued interest may amount to a significant percentage of NPP capital costs, especially if the construction project st reaches to half a decade or more. Small factory built reactors are expected to have shortened construction times, compared to large conventional reactors. Simplified advanced reactor designs are also expected to shorten NPP construction time. These shortening construction time can decrease the interest component of capital costs significantly.

Interest charges may reflect the market's assessment of project risks. The greater a projects assumed risk, the higher the interest premium the market will assess. By decreasing a project's size, and lowering projected manufacturing/construction time, nuclear project builders can offer the market lower perceived risks. Lower perceived risks, will lead to interest discounts compared to higher risk large nuclear projects.

Small, factory manufactured reactors offer advantages in transportation costs. Conventional reactors include a number of very large and heavy components, that present transportation challenges. Components such as pressure vessels and steam generators may require special and highly unusual transportation arrangements if they are transported overland. Special huge road transportation vehicles, some capable of moving no more than three miles an hour may disrupt highway uses in large areas over several weeks as they transported conventional reactor steam generators and pressure vessels to reactor sites. In contrast, small reactor cores may be moved by trucks or by rail as ordinary freight.

In areas where water shortages represent acute problems, small reactor access to reliable water supplies is unnecessary. Air cooling will enable small reactors to operate with out a reliable water supply.

Small reactor clusters located at recycled coal fire power plant locations potentially have greatly simplified grid connections. Not only can they be located near to the cities they are intended to serve, but grid hookup is facilitated by existing transformer farms, and grid connections. Because they can be located close to served cities new transmission lines will not cover long distances, thus lowering grid expansion costs. Large reactors may require new transmission lines that are hundreds of miles long, in order to move surplus electricity to market.

In addition to the above savings, and potential savings mentioned above there are other potential savings that may be available with small reactors. For example, with advanced nuclear technology, for example molten salt reactors, combined Rankine (steam) and Brayton (gas) cycles are possible. A bottoming desalinization cycle could be offered to to the system, thus offering formidable efficiency from small reactor packages. A high temperature reactor can provide top cycle heat for industrial processes, as well as producing middle cycle electricity generation, and bottom cycle heat for electrical generation. By adding a second generating cycle, small reactors can lower their electrical generation costs. Desalinization would add a further revenue stream from the reactors operation through the sale of portable water.

Thus it can be concluded that shifts to small nuclear power plants will potentially offer significant savings over current conventional nuclear costs. Shifts from conventional nuclear technology, to some advanced nuclear technologies, also offer significant potential savings. Some advanced technology savings are available to both large and small nuclear power plants, but the flexibility of small NPPs may mean that at least in certain situations small advanced nuclear power plants may offer very significant potential savings in comparison to large conventional NPPs.

Thus small factory produced advance reactors may offer a revolutionary approach to lowering nuclear costs. Economies of scale, often viewed as the only decisive factor in nuclear costs does not control many nuclear cost sources, and is unlikely to be a decisive approach to controlling nuclear costs. Numerous cost containment stratagies, some involving the factory construction of small reactors, but most compatible with small reactors can be drawn on to lower nuclear costs.

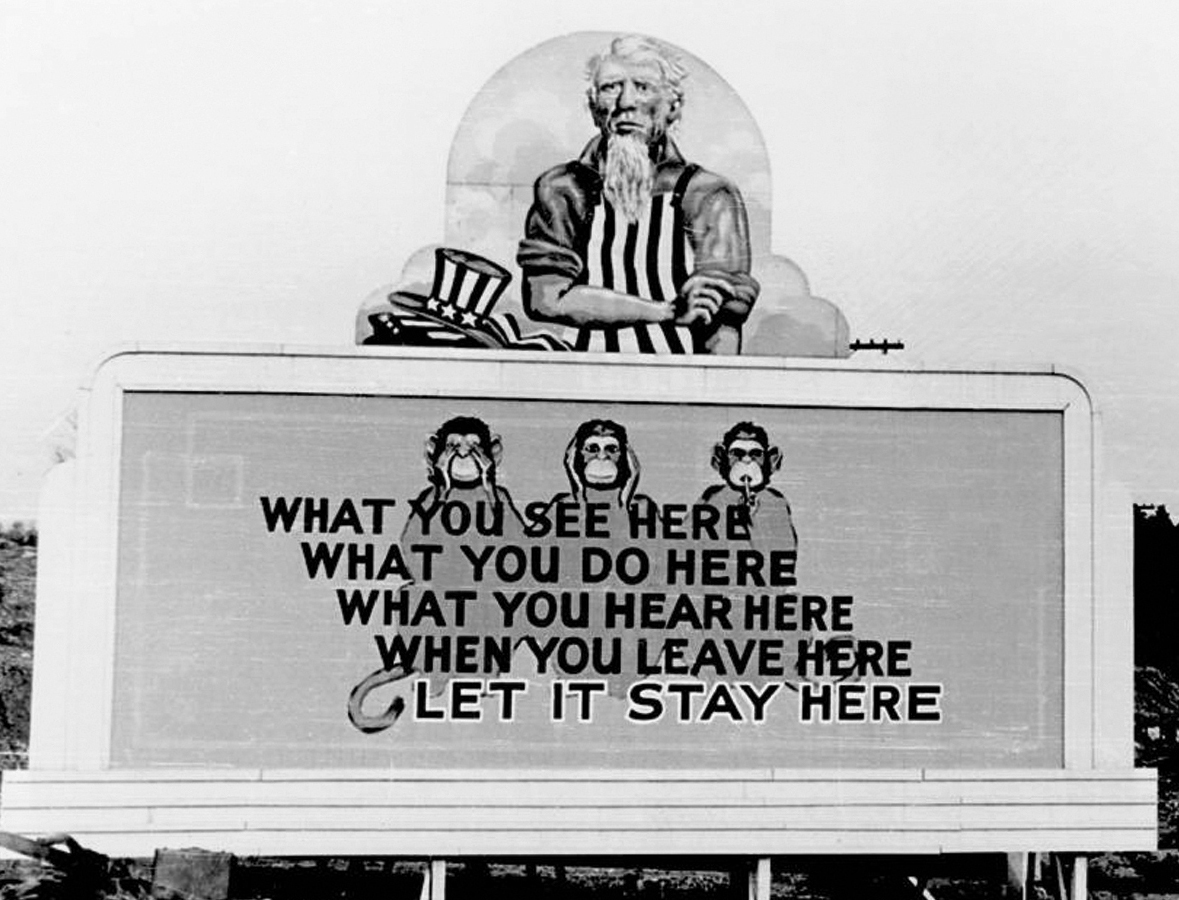

Sometime, not long after my father went to work as a chemist in Oak Ridge, I asked him what he did at work.

Sometime, not long after my father went to work as a chemist in Oak Ridge, I asked him what he did at work.

lt;span class=" error="" id="SPELLING_ERROR_48">sideviewJuly26.jpg]" border="0">

lt;span class=" error="" id="SPELLING_ERROR_48">sideviewJuly26.jpg]" border="0"> Monday Afternoon, I drove to ORNL to hear a presentation by Dr. Kazuo Furukawa and Keishiro Fukushima of the "

Monday Afternoon, I drove to ORNL to hear a presentation by Dr. Kazuo Furukawa and Keishiro Fukushima of the "