I am not sure why you think Weinberg was so correct about his safety concerns with light water reactors. Certainly they are not "inherently safe" and they require care in design, manufacturing and operation, but the safety record of the machines that caused Weinberg so much worry has been extraordinary all around the world.These comments were most unfortunate. Rod appears to have made this comment without being aware of a number of Nuclear Green posts that would have better established the relationship of the nuclear safety issues to Weinberg's firing. Since I have offered a number of reasonably well documented posts on Weinberg's firing, Rod seemingly has ignored the available evidence and has not offered other evidence in support of his contentions.

Sometimes I think that the real answer to why Weinberg was fired was that he was not a team player and was so sure of his own knowledge that he overlooked the fact that others were just as smart and just as concerned about the welfare of their fellow man.

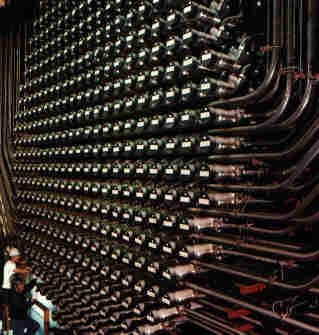

I cut my nuclear teeth on light water reactors. One of the most intellectually difficult tasks I had every year was coming up with some kind of reasonable scenario for our annually required "reactor accident" drill. My down to earth technicians and I just could not figure out how those thick stainless steel pipes were supposed to suddenly burst open.

Since my discussion of the evidence regarding the major actors in the Weinberg firing is quite extensive, I will point to relevant posts rather than discuss the evidence at length. First I noted what is arguably the unconstitutional authority which Congressman Chet Holifield exercised over the AEC. Hiring and firing decisions are made by persons with executive authority in an organization, yet Alvin Weinberg was invited to the office of a member of the legislative branch of government to be told that he was hired. Constitutionally, Congressman Holifield had no right to fire Alvin Weinberg. I have tried to point out that the safety nuclear safety conflict that formed part of the back drop of Weinberg's firing was not between and Weinberg and the Holifield clique, it was between the community of National Laboratory scientists. I have tried to lay out the issues that motivated that conflict. In fact Rod Adam's comment sheds some light on the attitude of Milton Shaw who played a major role in the safety conflict. Rod argued,

One of the most intellectually difficult tasks I had every year was coming up with some kind of reasonable scenario for our annually required "reactor accident" drill. My down to earth technicians and I just could not figure out how those thick stainless steel pipes were supposed to suddenly burst open.Robert Pool described the difference of attitudes between the national laboratory scientific community and ex-Navy reactor developer Milton Shaw,

Milton Shaw, the head of the AEC's Division of Reactor Development and Technology, was convinced that such safety research was reaching the point of diminishing returns. An old Rickover protege, Shaw saw light-water reactors as a mature technology. The key to the safety of commercial power plants, he thought, was the same thing that had worked so well for the navy reactor program: thick books of regulations specifying every detail of the reactors, coupled with careful oversight to make sure the regulations were followed to the letter.In fact the Three Mile Island accident was to show that the civilian Light Water Reactor had not reached a level of maturity comparable to that of Naval Light Water Reactors which Shaw (and Rod Adams) assumed.

Post Three Mile Island the civilian Light Water Reactor did reach an outstanding level of safety, but at a considerable cost. As I have documented, Alvin Weinberg's conflict with Milton Shaw had to do with an experiment which involved deliberately destroying a reactor in order to find out what happened. The worse case that concerned the scientists was the China syndrome, a core melting through all containment. A reactor was being built in Idaho in order to conduct this experiment. Shaw decided that the reactor was not needed, and stopped further construction. Dozens of National Laboratory scientists objected to the scrapping of what was considered an important nuclear safety experiment, and testified before Congress. Weinberg agreed with them, but did not take his disagreement to the level of Congressional testimony. Eventually the Three Mile Island accident was to substitute for for the Idaho nuclear accident experiment.

Rod tells us,

Considering the misconduct of all of the key players, the alligation that Weinberg was not a team player does not hold true. There is more evidence. The Nixon administration appears to have decided to attack the power of the Hloifield clique. When Ramsey's appointment came up for renewal, he was not reappointed by Nixon. His replacement was Dixie Lee Ray, who was soon appointed AEC Chairman. Ray proceeded to outmannuver Shaw, who was forced to resign. Holifield was shorn of his power and decided to not run for reelection in 1974. Ray, now had a chance to right the wrong done by the Weinberg firing episode, and she did so, by arranging for Weinberg to come to Washing as the first Director of Energy Research. Weinberg's appointment, if I am not mistaken involved directly reporting to the President. Weinberg was not happy with his position, and left it after a year, but this appointment should be taken as evidence that Weinberg was viewed as a team player.

Sometimes I think that the real answer to why Weinberg was fired was that he was not a team player and was so sure of his own knowledge that he overlooked the fact that others were just as smart and just as concerned about the welfare of their fellow man.My evidence suggests that Holiway, Ramsey and Shaw failed to exercise proper leadership. Holiway, as I have indicated exercised executive authority over the AEC even though he was not entitled to by the constitution. Ramsey's appointment as an AEC Commissioner had been dictated to the Kennedy Administration by Holifield. Ramsey was in fact a member of Holifield's staff, and after his appointment continued to engage in the subordinate relationship with Holifield, continuing to report to him. Shaw improperly turned decision making about a personnel matter, Weinberg's status as a National Laboratory Director to Holifield.

Considering the misconduct of all of the key players, the alligation that Weinberg was not a team player does not hold true. There is more evidence. The Nixon administration appears to have decided to attack the power of the Hloifield clique. When Ramsey's appointment came up for renewal, he was not reappointed by Nixon. His replacement was Dixie Lee Ray, who was soon appointed AEC Chairman. Ray proceeded to outmannuver Shaw, who was forced to resign. Holifield was shorn of his power and decided to not run for reelection in 1974. Ray, now had a chance to right the wrong done by the Weinberg firing episode, and she did so, by arranging for Weinberg to come to Washing as the first Director of Energy Research. Weinberg's appointment, if I am not mistaken involved directly reporting to the President. Weinberg was not happy with his position, and left it after a year, but this appointment should be taken as evidence that Weinberg was viewed as a team player.